Top Grade Plastic Water Tanks Manufacturer in India

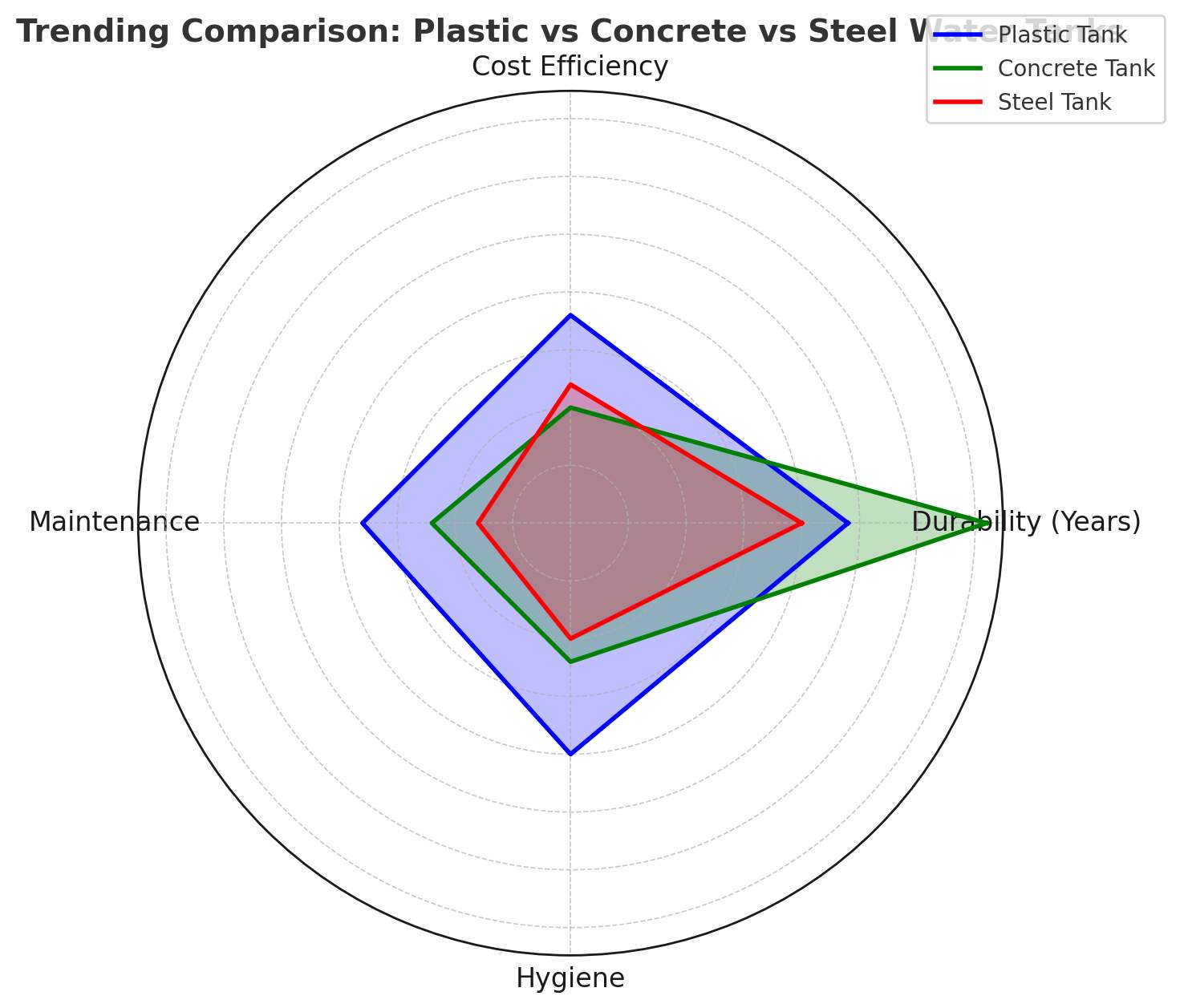

Plastic water tanks are preferred over metallic water tanks in a variety of industries, including agriculture, oil, and gas, water, waste treatment, medical, scientific, and pharmaceutical. Furthermore, water tanks are frequently utilized for purposes such as storing drinking water for residential and commercial installations, as well as rainwater storage.

They’re also commonly used for firefighting, water treatment, agricultural irrigation, and other water-related applications. Plastic water tanks, on the other hand, have significant drawbacks, such as low fire resistance and excessive heat absorption, which might change the temperature of the stored water. Despite the fact that plastic water tanks are a newer alternative than metal, having only been in production for ten years, they are swiftly becoming the favored choice.

A wide range of plastic materials can be used to make water tanks. Polyethylene and polypropylene are two of the most common plastic materials used to make water tanks. Because of its strength and structural versatility, polyethylene (PE), a light, chemical-resistant thermoplastic, is the most frequently used plastic for water tanks. It is obtainable in high-density polyethylene (HDPE), low density polyethylene (LDPE), and a variety of other varieties.

Other plastics, such as polypropylene (PP), polyvinyl chloride (PVC), and polyvinylidene fluoride (PVDF), are also long-lasting and trustworthy. Water tanks range in size and capacity from small tanks holding a few gallons to tanks measuring more than 35 feet long and storing 50,000 gallons or more. The water tank’s structure varies.

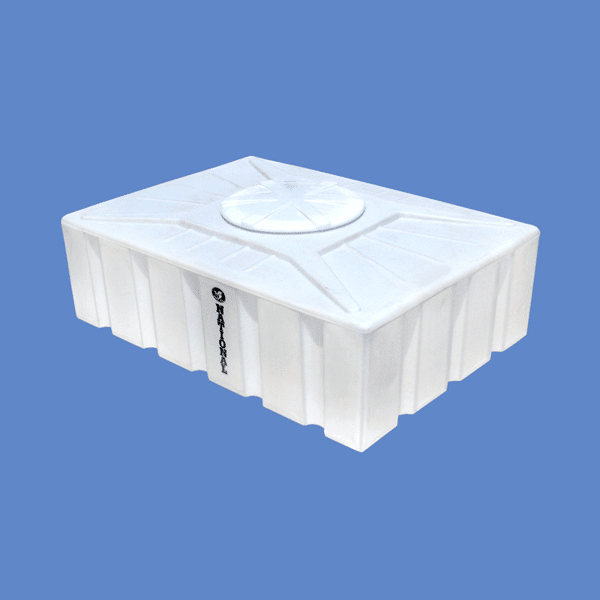

Cylindrical, square, rectangular, hexagonal, and octagonal tanks are common. Water tank heads and bottoms are also dissimilar depending on their uses. Conical bottom tanks, for example, which resemble a funnel, allow tank contents to flow quickly to the tank’s bottom, facilitating tank drainage. furthermore, additional tanks can be linked together when huge amounts of water are required.

Key Features of Plastic Water Tank

High Grade Food-Grade Plastic (LLDPE)

It is made of Linear Low-Density Polyethylene that is FDA approved, and thus it can be used to store drinking water as well as it does not contaminate the water.

Outer layer - UV-Stabilized

Constructed with UV-resistant coating to avoid fading and weathering caused by direct exposure to the sun, thus best to use outdoors in harsh Indian weather.

Multi-Layer Construction (3, 4, 5 Layers)

With multi-layer construction, tanks have an extended lifespan, given their safety from algae, and even temperature management of the water phase for hot and cold weather.

Leak-Proof & Rust-Free Body

Apart from being completely rust-free, plastic water tanks are formulated with completely leak-proof roto-milling technology, where there are no seams.

Lightweight and Strong

Since they are lightweight, they can be easily transported and put up, yet they have a lot of strength and impact resistance.

Odour-Free and Hygienic

This is especially owed to the odour-free and bacteria-free antimicrobial inner membranes that ensure that the water dispensed does not possess smell, taste, or even bacteria.

A Variety of Capacities (200L to 10,000L+)

Available in various forms and sizes, and the capacity varies between minimum and maximum available to suit any demands.

Friendly and Reusable

Manufactured in ecologically safe materials and recyclable, 100 % sustainable water storage solutions. Threaded lids with air vents should be secured, which will block all entry of dust and insects into the containers

Types of Plastic Tanks

Underground Plastic Water Tanks

Designed for space-saving and concealed installations.

Loft Water Tanks

Compact and ideal for installation in small spaces like home lofts.

Rectangular and Cylindrical Tanks

Available in different shapes to suit installation requirements.

Triple Layer Plastic Tanks

Advanced UV protection and hygienic water storage.

Tips for Selecting the Best Quality Plastic Water Tank

- Capacity Requirement – Consider according to family/Industrial Requirements.

- Quality of Materials – It is made from an FDA-approved, food-grade plastic.

- Number of Layers – Select multi-layerist rocket terms foo hot subtropicals.

- Brand & Warranty – Go for well-known manufacturers that give a long warranty.

| Capacity (Liters) | Suggested Use Case |

| 200 – 500 L | Small households, loft storage |

| 500 – 1000 L | Medium family water needs |

| 1000 – 5000 L | Large families, apartments, small farms |

| 5000 – 10,000 L | Agriculture, hotels, and small industries |

| 10,000 – 20,000 L | Industrial use, factories, rainwater storage |

The Advantages of Plastic Water Tanks

- Pollution-free and safe drinking water

- Long-lived, having a life span of 10-15 years.

- Covered in a variety of colors (black, white, blue, green) to deal with particular requirements (e.g,. black tanks inhibit the growth of algae).

- Environmentally friendly– A lot of tanks can be recycled at the end of their lives.

Applications

Domestic: Use of water, kitchen storage, and bathroom.

Commercial Buildings: Hotels, hospitals, and offices.

Agricultural Use: Irrigation, mixing pesticides, and spraying.

Industrial Application: Storage of water in the processing and cooling system.

Construction Sites: Supply and storage of tectonic water.

What are the latest innovations in plastic water tank materials for durability in 2025

Currently, the recent trends in plastic water tank durability in 2025 involve the use of quality, sophisticated, durable polymers in parallel with special treatments such as coatings and structural reinforcing, where the tank will be subjected to severe conditions and durable tank performance. Important material innovations are:

Optimal Polymer

Tanks are mainly constructed using enhanced grades of high-density polyethylene (HDPE) and, in some cases, medium-density polyethylene (MDPE) that have been designed to crack, impact, leak, and degrade in chemical environments better than the previous models.

UV-Resistant Coating

Newer tanks have UV-resistant coatings or layers which stop UV-damage to the plastic, keeping it strong and new-like even after years under the rays of the sun, with effects similar to an UV-proof version of Effect

Condensed Coatings and Lining

New technologies like micro-polymer and antimicrobial coating promote durability since they prevent microbial growth, proliferation of algae and contamination of the tank internally, along with heightening resistance to both chemicals and impact.

Multi-layer Rotational Molding

Current manufacturing processes related to tanks is likely to employ rotational mold technology in multi-layer types to produce the inner lining and layers of the tank to maintain safety in water and outer sheathings in building the structure and its tolerance to the elements, avoiding the cracking and leakages in such items during long-term application.

Impact-Resistant Technology

Formula changes and structural improvements add more protection by bringing to the fore, protection against physical impact and tough handling, and as a result, a tank is more trustworthy in a variety of conditions.

Circular economy

Circular economy is based on recyclable and eco-friendly polymers that are durable and do not jeopardize the environmental objectives, which there is an upward shift in the direction of the tank manufacturing process.

Smart Monitoring Integration

In what is not technically a material, tanks are now commonly designed with smart sensor mounts into their tank design, using compatible, durable plastics, to improve ease of management and maintenance at no compromise to tank performance.

The above innovations help to produce more rugged, weather-resistant, hygienic, and affordable sustainable plastic water tanks in 2025 than in the past generations. This development justifies longer service life, reduced maintenance and improved water quality of storage in residential, agricultural, commercial and industrial use.